FV350-160 Automatic Inline Orbital Wrapping Machine

Ideal for long products pipes, tubes, timber boards and frames

- 1600 mm diameter ring

- Wrap up to 1.8x faster with twin film dispensers

- Adjustable film tension

- Automatic film clamp and cut

- View machine specifications and options >>

Dimensions

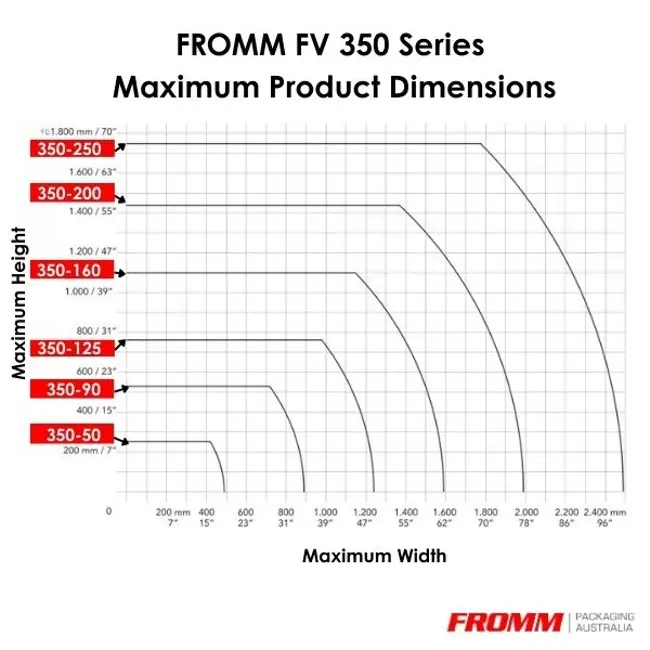

Min. 360x360 mm (WxH);__ Max. 1150x1100 mm (WxH)

Purchase Options

Buy or rent

Two Year Warranty

Simulation Testing

5 Star Rated

Environmentally Friendly

Features

- Double reel film dispensers

- 1600mm wrapping ring

- Adjustable speed up to 60 RPM

- Mechanical film brake

- Automatic start

- Automatic film clamp and cut

- To be placed in production line

- Six wrapping programs available

- Touch screen control panel

- Safety system

Options

- Powered infeed and outfeed conveyors - range of options

- Manual or automatic top pressers to stabilise load

- Manual or automatic side rollers to guide or group product

- Bridge for short products

- Automatic blocks dispenser

- Automatic top and bottom bubblewrap dispenser

- Film reel end warning light

Benefits

- Wrap up to 1.8x faster with double reel film dispensers

- Easy operation

- Fast roll changes (no tools required)

- Automatic features and programmable wrapping patterns

- Range of additional options

- FROMM 2 year warranty

Machine Specification

1600 mm

W: 1150 mm , H: 1100 mm, L: Unlimited

W: 360 mm, H: 360 mm, L: 600 mm

5 - 60 RPM

Included

Dependent on conveyors

250 mm / 150 mm / 100 mm

415 / 50 Hz / 3 Phase

6 Bars

Included

Machine Options

For infeed and outfeed - range of types

Manual or automatic to guide or group product

Manual or automatic to stabilise load in wrapping cycle

For products < 600 mm in length

For wooden or porex blocks

To protect product before wrapping cycle

Available

Plastic stretch wrap is an integral material for safe and secure pallet load containment. FROMM’s high quality, tear resistant stretch wrap is capable of significant stretch without compromising product integrity for suitable products.

Bundled with our wrapping machines, our customers use less film, resulting in reduced packaging and waste disposal costs. Enhanced film stretchability means less material is required overall, and precise product usage enabled by our wrapping machines minimises unnecessary waste

Reduce: Reviewing the film thickness can significantly reduce the amount of plastic needed, providing the same performance as thicker films.

Reuse: While most stretch wrap is designed for single use, we encourage reusing leftover wrap for smaller, in-house applications where feasible, helping extend its life before disposal.

Recycle: FROMM Verde stretch films are made with 30% post-consumer recycled (PCR) material and are fully recyclable under the recycling code LLDPE (4). We promote proper recycling practices and work with our customers to ensure that used film enter the recycling stream whenever possible.

Need the perfect packaging solution? Let's wrap this up!

Share your details below, and our packaging experts

get back with the solution .

You might also be interested in

FV350-200

Automatic Inline Orbital Wrapping Machine

Ideal for process lines wrapping metal sheets, doors or timber

FV350-90

Automatic Inline Orbital Wrapping Series

Ideal for small process lines with long pipes, tubes or rods