Machines & Automation

The FROMM P328 Battery Powered Plastic Strapping Tool features the latest strapping tool technology. Packed with features including automatic cooling in the event of motor overload, brushless motors, and a new strap release function to maximise strap tension on the product.

For bricks, timber, tiles, bales, aluminium, steel and general strapping the P328 is the solution. Approximately 350 cycles per charge and fast recharging the P328 is making strapping and load restraint easier than before.

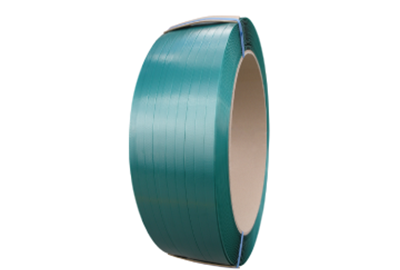

Backed up by FROMM Packaging Australia, rent or purchase options, the P328 delivers for the Australian industry. For best results we recommend our STARstrap-Plus range of premium PET strap.

All equipment is supported by our on-site mobile service team and spare parts are readily available.

A Pallet Wrapping machine is economical and efficient way to of securing loads on a pallet. A Pallet Wrapping Machine will wrap your products on a pallet using a plastic stretch film to enable protection during transit and the best way of ensuring load integrity.

From an WH&S prospective, try walking around a pallet waving a 3 KG roll of plastic, perhaps 10 revolutions and with a dizzy head you have probably answered your question. If your despatch department is wrapping multiple pallets per day, a simple stretch wrapping machine would make life easier and safer.

Other important elements to consider are -

From a presentation point of view pallets wrapped by hand are different almost every time when pallets wrapped by a machine present consistently. A stretch wrapping machine can unitise the a pallet to the same standard time after time.

From a load integrity prospective, a pallet wrapped by machine you can regulate how it is wrapped and how much film you have applied to ensure load stability. When doing the same by hand, even with the most diligent employee it's hard to get it right.

From an environmental prospective a wrapping machine will usually give you a better safer product using less plastic than by hand. Less plastic means less waste, simple really.

From the all-important cost prospective, a machine can save you around 40% in film costs compared to wrapping by hand. Do the numbers just in film savings and you will see a benefit. Take into account what else your employee could be doing instead of walking around a pallet, you have productivity savings too.

Finally, with COVID19 and social distancing laws in place, you can keep your employees separated by using machines and limit the need to gather in busy despatch areas.

Just submit your contact details and we’ll be in touch shortly with more information