Pallet Load Containment

Pallet load containment is the combined forces that keep a pallet together during storage & transport. In order to achieve load containment, stacked products on a pallet need to be unitised by a form of restraint to become one "load" or "logistic unit". Pallets are most commonly unitised with stretch wrapping as it is economical and provides the most effective pallet load containment when used correctly.

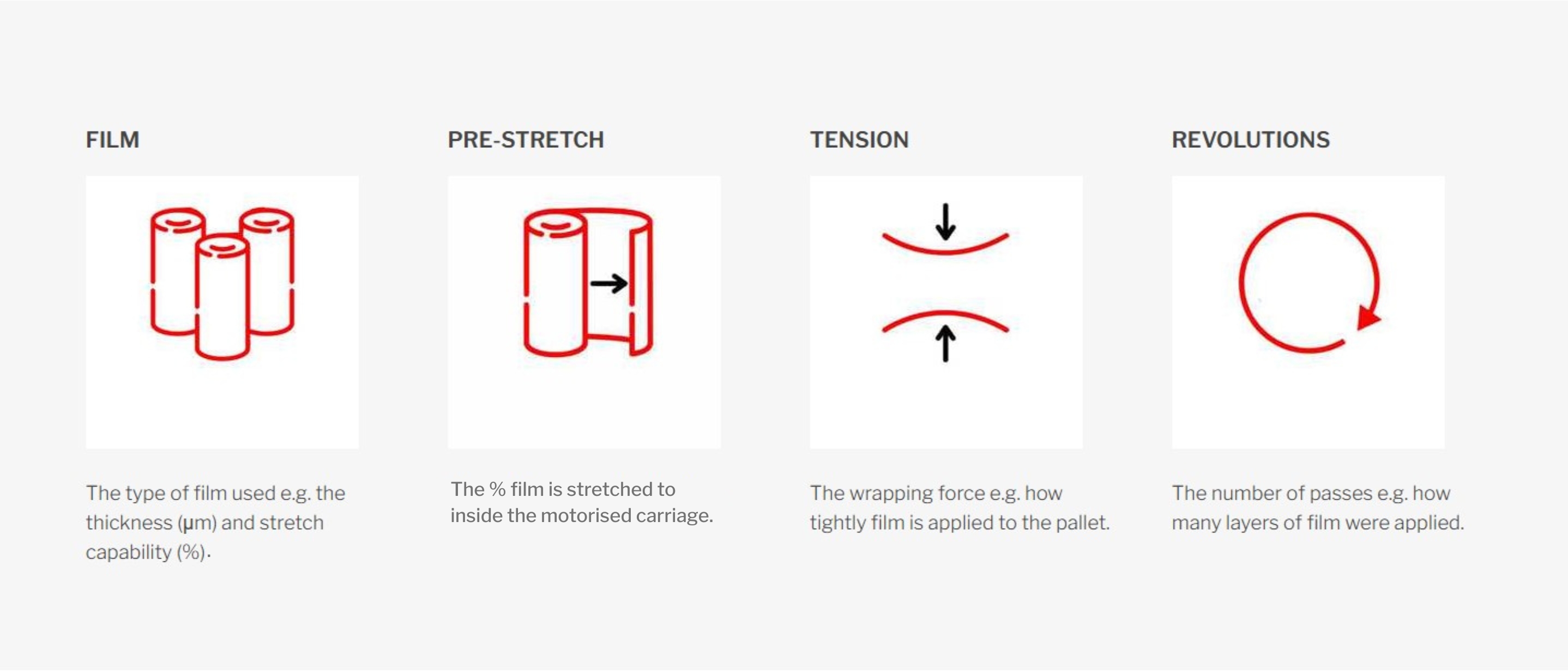

To achieve pallet load containment with stretch film there are four factors to consider:

These factors are highly dependent on the type of product, load stability and the intended function of the film e.g. protection for extended storage vs transporting directly to the customer to distribute.

Wrapping Checklist

✅ Wrap from bottom to top

Secure film to the pallet and wrap the entire stacked height including the top 30-50% of the wooden pallet.

✅ Overlap Wrap Layers

Ensure each layer of stretch wrap overlaps the previous one by about 50%. This provides security and stability.

✅ Secure dags & tails

Secure the film at the end of the wrapping cycle to the pallet.

Wrapping Standard

Wrapping Standard

To transport palletised goods, load containment must meet Performance Standards set by the National Transport Commission (NTC). These standards are to ensure pallets are properly restrained to withstand forces in the event of stress during transportation.

Learn what wrapping standards apply under the Requirements section.

Testing Pallet Load Containment

The most efficient way to confirm pallet load containment is to test pallets on simulation equipment.

This equipment tests pallets against the forces outlined within the Performance Standards set by the NTC, and can confirm compliance with customer or internal wrapping standards. In the case that pallets fail these tests, recommendations to improve load containment is provided.

Shipping Simulator

Simulates G-forces through tilt testing pallets to the NTC guidelines.

Pallet Load Containment Cube

Measures compression force and puncture resistance of the applied film.